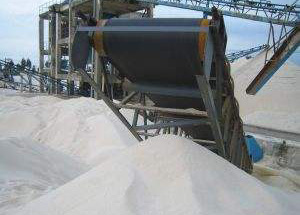

1.Raw Material

The followings are the main materials

Sand

Soda ash

Used glass

Glass bottles form naturally. We take responsibility for the environment by recycling used glass.

2. Melting

The temperature in the middle part of the furnace is over 1500°C and the raw materials will be melted inside. The furnaces run 24 hours per day, 365 days per year without stop.

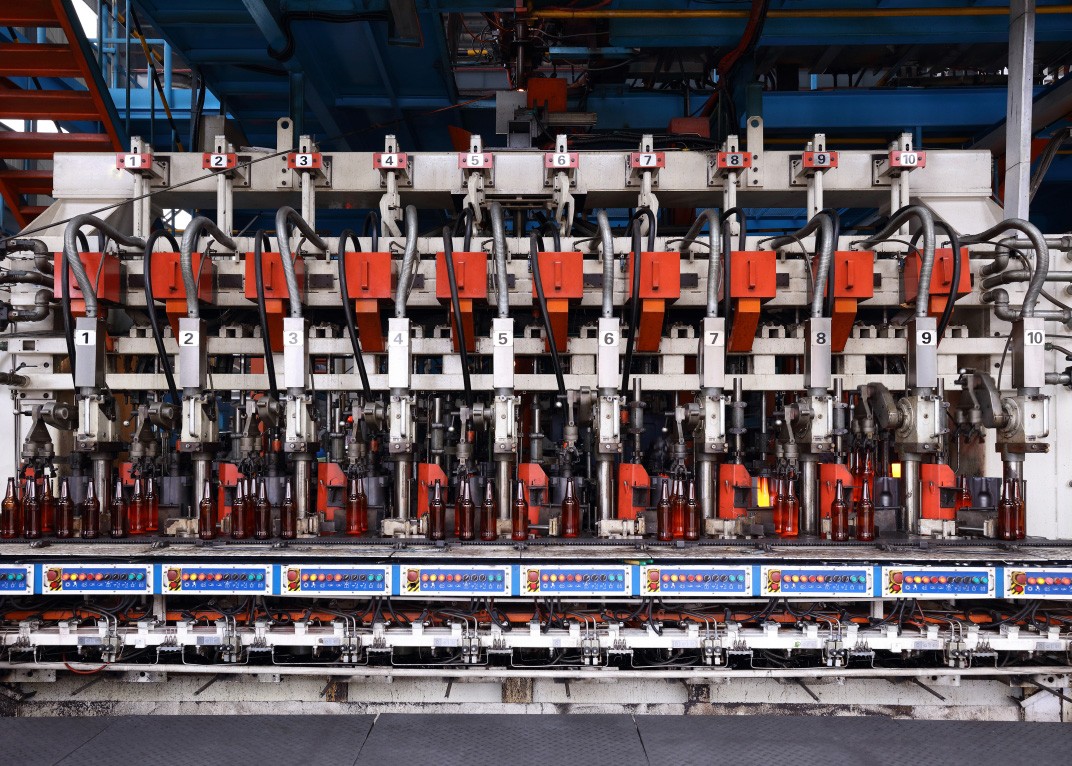

3. Forming

The forming machine is called IS machine. One of the important parts are the molds. When the glass liquid drops into the molds, it forms based on the shape of the molds. We use two different techniques which are pressing and blowing depends on the bottle shapes.

4. Annealing/Cooling

The glass bottles are very hot when they are just made from the IS machine and the temperature needs to go down gradually to make the bottles strong and heat resistant enough. That is the function of an annealing/cooling machine.